LiNK Inspection

LEGISLATIVE INSPECTION FRAMEWORK IN BELGIUM

Three inspection domains are legally determined Belgium

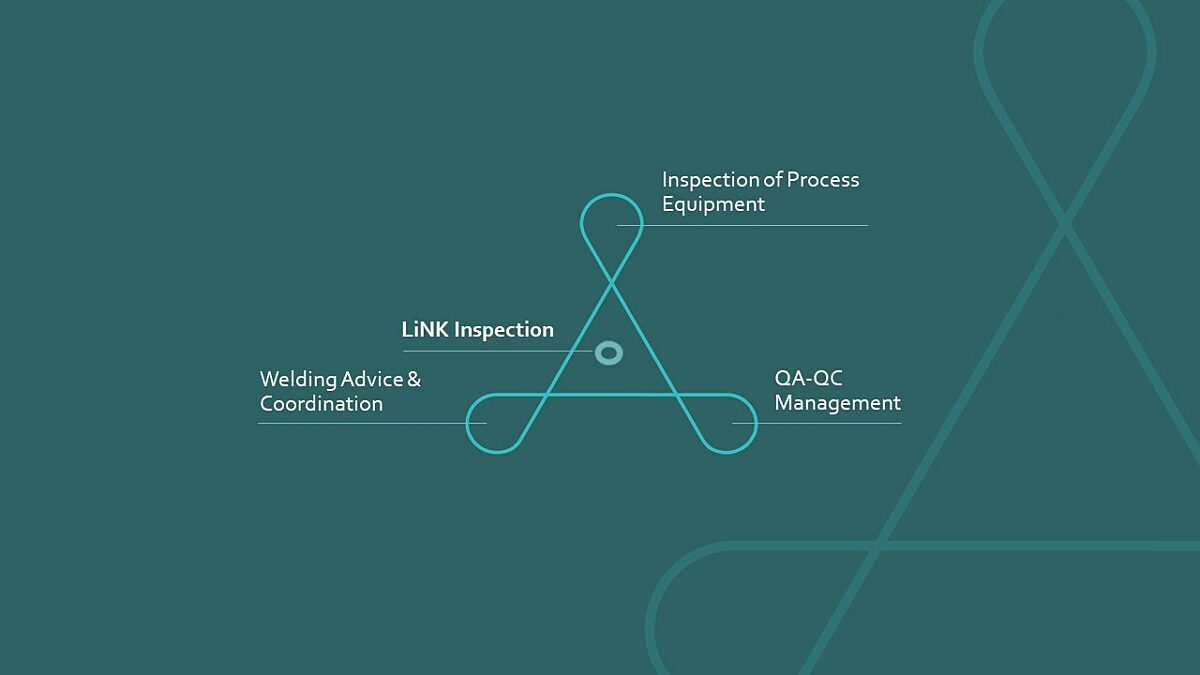

LINK INSPECTION SERVICES

Inspection of process equipment

Welding advice & coordination

QA-QC management

ADDED VALUE WITH LINK INSPECTION

Although over 80% of all production units are not submitted to legally determined inspection LiNK Inspection is able to offer added value by introducing low budgets. Moreover, LiNK Inspection is your partner in planning and executing inspection, in order to